Specifying and Project Management of a Fully Automated Metals Processing Line

Client

Australia's Premier Lighting Manufacturer

Services provided

Background

Australia’s defence industry was in a position in to take advantage of a number of defence related opportunities flowing from such projects as JSF. The immediate issue was that the country did not have a suitable metals processing plant. As a result materials would have to be shipped back and forth from the USA or the UK for processing. This was not a financially viable, nor timely solution. KAL Global’s directors had extensive relationships with a number of offshore metals processing plants and were engaged at the time by one of Australia’s defence prime contractors to investigate world’s best practice and put out to tender for a new locally based processing plant located in Wingfield SA.

The Challenge

KAL Global was engaged to determine the optimal solution for the requirements. This initially involved traveling the globe and investigating processing plants in the USA, Germany, India and the UK and incorporating the world’s best practice in these plants for adoption at the Wingfield facility.

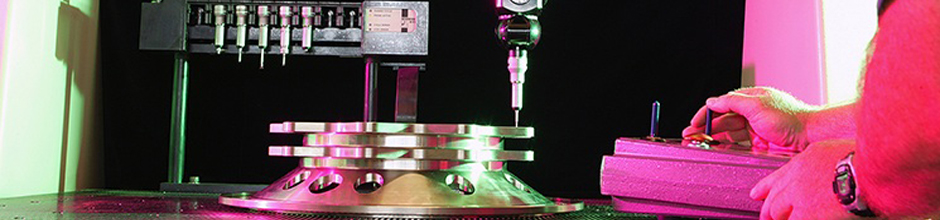

The Solution

The solution was a fully automated tank line and paint facility located in Wingfield SA. KAL Global, in conjunction with the prime contractor project managed the build and installation of the metals processing facility. Commissioning was then handed over to the defence prime contractor.

Results

The Wingfield plant is arguably the most advanced metals processing plant in the southern hemisphere and has facilitated a number of $multi million contracts.